From The DOE’s Lawrence Berkeley National Laboratory

4.22.24

Aliyah Kovner

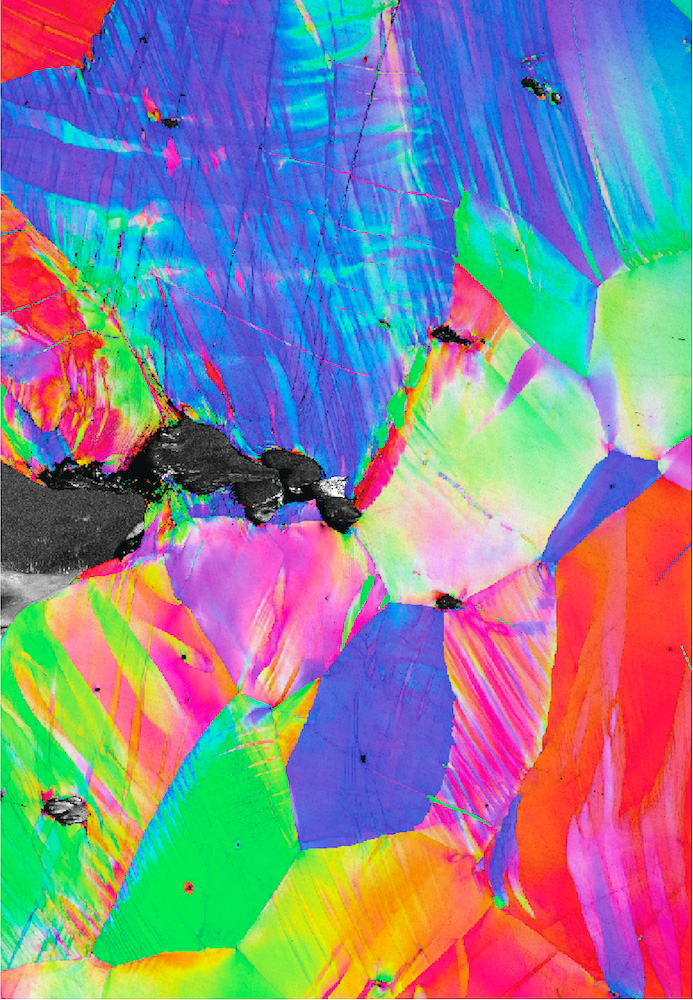

A map of the crystal structure of the alloy made with electron backscatter diffraction in a scanning electron microscope. Each color represents a section of the crystal where the repeating structure changes its 3D orientation. Credit: Berkeley Lab

Researchers have uncovered a remarkable metal alloy that won’t crack at extreme temperatures due to kinking, or bending, of crystals in the alloy at the atomic level

________________________________

Key Takeaways

-Unlike most materials, the new alloy keeps its shape and resists cracking at both high and low temperature extremes, making it potentially suitable for demanding applications like high-efficiency aerospace engines.

-This alloy is one of the toughest materials on record, with a resistance to cracking on-par with cryogenic steels.

-Microscopy reveals that a type of defect in the material’s structure historically thought to promote fracture in reality does the opposite and is responsible for its high toughness.

________________________________

A metal alloy composed of niobium, tantalum, titanium, and hafnium has shocked materials scientists with its impressive strength and toughness at both extremely hot and cold temperatures, a combination of properties that seemed so far to be nearly impossible to achieve. In this context, strength is defined as how much force a material can withstand before it is permanently deformed from its original shape, and toughness is its resistance to fracturing (cracking). The alloy’s resilience to bending and fracture across an enormous range of conditions could open the door for a novel class of materials for next-generation engines that can operate at higher efficiencies.

The team, led by Robert Ritchie at Lawrence Berkeley National Laboratory (Berkeley Lab) and UC Berkeley, in collaboration with the groups led by professors Diran Apelian at UC Irvine and Enrique Lavernia at Texas A&M University, discovered the alloy’s surprising properties and then figured out how they arise from interactions in the atomic structure. Their work is described in a study that was published April 11, 2024 in Science.

“The efficiency of converting heat to electricity or thrust is determined by the temperature at which fuel is burned – the hotter, the better. However, the operating temperature is limited by the structural materials which must withstand it,” said first author David Cook, a Ph.D. student in Ritchie’s lab. “We have exhausted the ability to further optimize the materials we currently use at high temperatures, and there’s a big need for novel metallic materials. That’s what this alloy shows promise in.”

The alloy in this study is from a new class of metals known as refractory high or medium entropy alloys (RHEAs/RMEAs). Most of the metals we see in commercial or industrial applications are alloys made of one main metal mixed with small quantities of other elements, but RHEAs and RMEAs are made by mixing near-equal quantities of metallic elements with very high melting temperatures, which gives them unique properties that scientists are still unraveling. Ritchie’s group has been investigating these alloys for several years because of their potential for high-temperature applications.

“Our team has done previous work on RHEAs and RMEAs and we have found that these materials are very strong, but generally possess extremely low fracture toughness, which is why we were shocked when this alloy displayed exceptionally high toughness,” said co-corresponding author Punit Kumar, a postdoctoral researcher in the group.

According to Cook, most RMEAs have a fracture toughness less than 10 MPa√m, which makes them some of the most brittle metals on record. The best cryogenic steels, specially engineered to resist fracture, are about 20 times tougher than these materials. Yet the niobium, tantalum, titanium, and hafnium (Nb45Ta25Ti15Hf15) RMEA alloy was able to beat even the cryogenic steel, clocking in at over 25 times tougher than typical RMEAs at room temperature.

But engines don’t operate at room temperature. The scientists evaluated strength and toughness at five temperatures total: -196°C (the temperature of liquid nitrogen), 25°C (room temperature), 800°C, 950°C, and 1200°C. The last temperature is about 1/5 the surface temperature of the sun.

The team found that the alloy had the highest strength in the cold and became slightly weaker as the temperature rose, but still boasted impressive figures throughout the wide range. The fracture toughness, which is calculated from how much force it takes to propagate an existing crack in a material, was high at all temperatures.

Unraveling the atomic arrangements

Almost all metallic alloys are crystalline, meaning that the atoms inside the material are arranged in repeating units. However, no crystal is perfect, they all contain defects. The most prominent defect that moves is called the dislocation, which is an unfinished plane of atoms in the crystal. When force is applied to a metal it causes many dislocations to move to accommodate the shape change. For example, when you bend a paper clip which is made of aluminum, the movement of dislocations inside the paper clip accommodates the shape change. However, the movement of dislocations becomes more difficult at lower temperatures and as a result many materials become brittle at low temperatures because dislocations cannot move. This is why the steel hull of the Titanic fractured when it hit an iceberg. Elements with high melting temperatures and their alloys take this to the extreme, with many remaining brittle up to even 800°C. However, this RMEA bucks the trend, withstanding snapping even at temperatures as low as liquid nitrogen (-196°C).

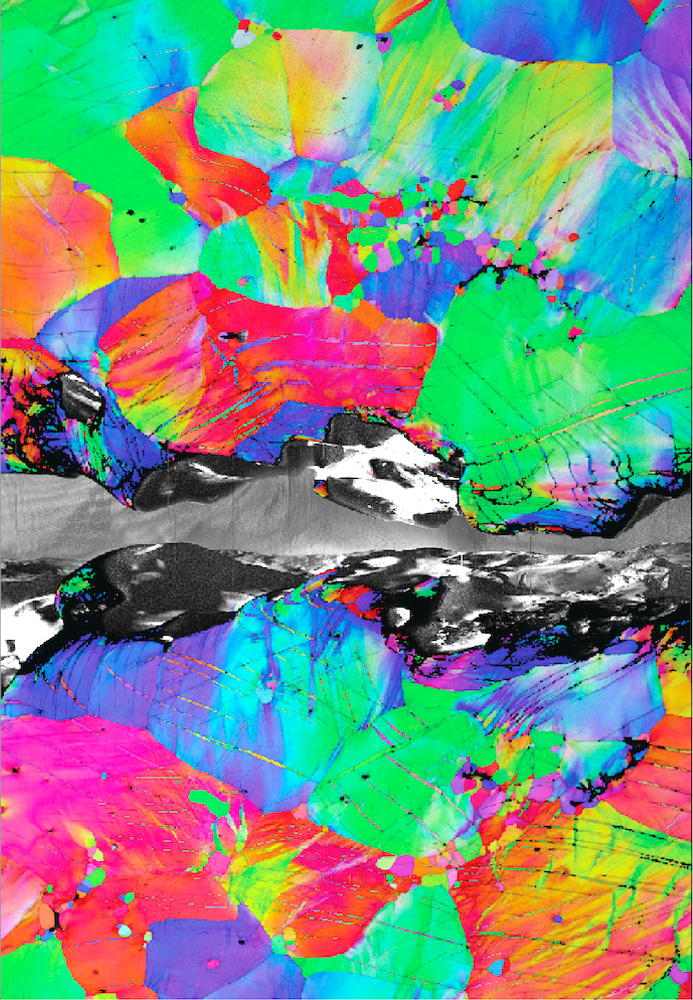

This material structure map shows kink bands formed near a crack tip during crack propagation (from left to right) in the alloy at 25 C, room temperature. Made with a electron-backscatter diffraction detector in a scanning electron microscope.

This map shows kink bands formed near a crack tip during crack propagation testing (from left to right) in the alloy at -196 C.

To understand what was happening inside the remarkable metal, co-investigator Andrew Minor and his team analyzed the stressed samples, alongside unbent and uncracked control samples, using four-dimensional scanning transmission electron microscopy (4D-STEM) and scanning transmission electron microscopy (STEM) at the National Center for Electron Microscopy, part of Berkeley Lab’s Molecular Foundry.

The electron microscopy data revealed that the alloy’s unusual toughness comes from an unexpected side effect of a rare defect called a kink band. Kink bands form in a crystal when an applied force causes strips of the crystal to collapse on themselves and abruptly bend. The direction in which the crystal bends in these strips increases the force that dislocations feel, causing them to move more easily. On the bulk level, this phenomenon causes the material to soften (meaning that less force has to be applied to the material as it is deformed). The team knew from past research that kink bands formed easily in RMEAs, but assumed that the softening effect would make the material less tough by making it easier for a crack to spread through the lattice. But in reality, this is not the case.

“We show, for the first time, that in the presence of a sharp crack between atoms, kink bands actually resist the propagation of a crack by distributing damage away from it, preventing fracture and leading to extraordinarily high fracture toughness,” said Cook.

The Nb45Ta25Ti15Hf15 alloy will need to undergo a lot more fundamental research and engineering testing before anything like a jet plane turbine or SpaceX rocket nozzle is made from it, said Ritchie, because mechanical engineers rightfully require a deep understanding of how their materials perform before they use them in the real world. However, this study indicates that the metal has potential to build the engines of the future.

This research was conducted by David H. Cook, Punit Kumar, Madelyn I. Payne, Calvin H. Belcher, Pedro Borges, Wenqing Wang, Flynn Walsh, Zehao Li, Arun Devaraj, Mingwei Zhang, Mark Asta, Andrew M. Minor, Enrique J. Lavernia, Diran Apelian, and Robert O. Ritchie, scientists at Berkeley Lab, UC Berkeley, the DOE’s Pacific Northwest National Laboratory, and UC Irvine, with funding from the Department of Energy (DOE) Office of Science. Experimental and computational analysis was conducted at the Molecular Foundry and the National Energy Research Scientific Computing Center – both are DOE Office of Science user facilities.

See the full article here .

Comments are invited and will be appreciated, especially if the reader finds any errors which I can correct.

five-ways-keep-your-child-safe-school-shootings

Please help promote STEM in your local schools.

Bringing Science Solutions to the World

In the world of science, The Lawrence Berkeley National Laboratory (Berkeley Lab) is synonymous with “excellence.” A number of Nobel prizes are associated with Berkeley Lab. Lab scientists are members of the The National Academy of Sciences, one of the highest honors for a scientist in the United States. A number of our scientists have won the National Medal of Science, our nation’s highest award for lifetime achievement in fields of scientific research. A number of our engineers have been elected to the The National Academy of Engineering, and a number of our scientists have been elected into The Institute of Medicine. In addition, Berkeley Lab has trained thousands of university science and engineering students who are advancing technological innovations across the nation and around the world.

Berkeley Lab is a member of the national laboratory system supported by The DOE through its Office of Science. It is managed by the University of California-Berkeley and is charged with conducting unclassified research across a wide range of scientific disciplines. Located on a 202-acre site in the hills above The University of California-Berkeley campus that offers spectacular views of the San Francisco Bay, Berkeley Lab employs a large number of scientists, engineers and support staff. Technologies developed at Berkeley Lab have generated billions of dollars in revenues, and thousands of jobs. Savings as a result of Berkeley Lab developments in lighting and windows, and other energy-efficient technologies, have also been in the billions of dollars.

Berkeley Lab was founded in 1931 by Ernest Orlando Lawrence, a University of California-Berkeley physicist who won the 1939 Nobel Prize in physics for his invention of the cyclotron, a circular particle accelerator that opened the door to high-energy physics. It was Lawrence’s belief that scientific research is best done through teams of individuals with different fields of expertise, working together. His teamwork concept is a Berkeley Lab legacy that continues today.

History

1931–1941

The laboratory was founded on August 26, 1931, by Ernest Lawrence, as the Radiation Laboratory of the University of California-Berkeley, associated with the Physics Department. It centered physics research around his new instrument, the cyclotron, a type of particle accelerator for which he was awarded the Nobel Prize in Physics in 1939.

LBNL 88 inch cyclotron.

Throughout the 1930s, Lawrence pushed to create larger and larger machines for physics research, courting private philanthropists for funding. He was the first to develop a large team to build big projects to make discoveries in basic research. Eventually these machines grew too large to be held on the university grounds, and in 1940 the lab moved to its current site atop the hill above campus. Part of the team put together during this period includes two other young scientists who went on to establish large laboratories; J. Robert Oppenheimer founded The DOE’s Los Alamos Laboratory, and Robert Wilson founded The DOE’s Fermi National Accelerator Laboratory.

1942–1950

Leslie Groves visited Lawrence’s Radiation Laboratory in late 1942 as he was organizing the Manhattan Project, meeting J. Robert Oppenheimer for the first time. Oppenheimer was tasked with organizing the nuclear bomb development effort and founded today’s DOE Los Alamos National Laboratory to help keep the work secret. At the RadLab, Lawrence and his colleagues developed the technique of electromagnetic enrichment of uranium using their experience with cyclotrons. The “calutrons” (named after the University) became the basic unit of the massive Y-12 facility in Oak Ridge, Tennessee. Lawrence’s lab helped contribute to what have been judged to be the three most valuable technology developments of the war (the atomic bomb, proximity fuse, and radar). The cyclotron, whose construction was stalled during the war, was finished in November 1946. The Manhattan Project shut down two months later.

1951–2018

After the war, the Radiation Laboratory became one of the first laboratories to be incorporated into the Atomic Energy Commission (AEC) (now The Department of Energy . The most highly classified work remained at Los Alamos, but the RadLab remained involved. Edward Teller suggested setting up a second lab similar to Los Alamos to compete with their designs. This led to the creation of an offshoot of the RadLab (now The DOE’s Lawrence Livermore National Laboratory) in 1952. Some of the RadLab’s work was transferred to the new lab, but some classified research continued at Berkeley Lab until the 1970s, when it became a laboratory dedicated only to unclassified scientific research.

Shortly after the death of Lawrence in August 1958, the UC Radiation Laboratory (both branches) was renamed the Lawrence Radiation Laboratory. The Berkeley location became the Lawrence Berkeley Laboratory in 1971, although many continued to call it the RadLab. Gradually, another shortened form came into common usage, LBNL. Its formal name was amended to Ernest Orlando Lawrence Berkeley National Laboratory in 1995, when “National” was added to the names of all DOE labs. “Ernest Orlando” was later dropped to shorten the name. Today, the lab is commonly referred to as “Berkeley Lab”.

The Alvarez Physics Memos are a set of informal working papers of the large group of physicists, engineers, computer programmers, and technicians led by Luis W. Alvarez from the early 1950s until his death in 1988. Over 1700 memos are available on-line, hosted by the Laboratory.

The lab remains owned by the Department of Energy , with management from the University of California-Berkeley. Companies such as Intel were funding the lab’s research into computing chips.

Science mission

From the 1950s through the present, Berkeley Lab has maintained its status as a major international center for physics research, and has also diversified its research program into almost every realm of scientific investigation. Its mission is to solve the most pressing and profound scientific problems facing humanity, conduct basic research for a secure energy future, understand living systems to improve the environment, health, and energy supply, understand matter and energy in the universe, build and safely operate leading scientific facilities for the nation, and train the next generation of scientists and engineers.

The Laboratory’s 20 scientific divisions are organized within six areas of research: Computing Sciences; Physical Sciences; Earth and Environmental Sciences; Biosciences; Energy Sciences; and Energy Technologies. Berkeley Lab has six main science thrusts: advancing integrated fundamental energy science; integrative biological and environmental system science; advanced computing for science impact; discovering the fundamental properties of matter and energy; accelerators for the future; and developing energy technology innovations for a sustainable future. It was Lawrence’s belief that scientific research is best done through teams of individuals with different fields of expertise, working together. His teamwork concept is a Berkeley Lab tradition that continues today.

Berkeley Lab operates five major National User Facilities for the DOE Office of Science:

The Advanced Light Source (ALS) is a synchrotron light source with 41 beam lines providing ultraviolet, soft x-ray, and hard x-ray light to scientific experiments.

The ALS is one of the world’s brightest sources of soft x-rays, which are used to characterize the electronic structure of matter and to reveal microscopic structures with elemental and chemical specificity. About 2,500 scientist-users carry out research at ALS every year. Berkeley Lab is proposing an upgrade of ALS which would increase the coherent flux of soft x-rays by two-three orders of magnitude.

Berkeley Lab Laser Accelerator (BELLA) Center

The DOE Joint Genome Institute supports genomic research in support of the DOE missions in alternative energy, global carbon cycling, and environmental management. The JGI’s partner laboratories are Berkeley Lab, the DOE’s Lawrence Livermore National Laboratory, the DOE’s Oak Ridge National Laboratory (ORNL), the DOE’s Pacific Northwest National Laboratory (PNNL), and the DOE’s HudsonAlpha Institute for Biotechnology . The JGI’s central role is the development of a diversity of large-scale experimental and computational capabilities to link sequence to biological insights relevant to energy and environmental research. A large number of scientist-users take advantage of JGI’s capabilities for their research every year.

The LBNL Molecular Foundry is a multidisciplinary nanoscience research facility. Its seven research facilities focus on Imaging and Manipulation of Nanostructures; Nanofabrication; Theory of Nanostructured Materials; Inorganic Nanostructures; Biological Nanostructures; Organic and Macromolecular Synthesis; and Electron Microscopy. Approximately 700 scientist-users make use of these facilities in their research every year.

The DOE’s NERSC National Energy Research Scientific Computing Center is the scientific computing facility that provides large-scale computing for the DOE’s unclassified research programs. Its current systems provide over 3 billion computational hours annually. NERSC supports 6,000 scientific users from universities, national laboratories, and industry.

DOE’s NERSC National Energy Research Scientific Computing Center at Lawrence Berkeley National Laboratory.

NERSC is a DOE Office of Science User Facility.

The DOE’s Energy Science Network is a high-speed network infrastructure optimized for very large scientific data flows. ESNet provides connectivity for all major DOE sites and facilities, and the network transports roughly 35 petabytes of traffic each month.

Berkeley Lab is the lead partner in the DOE’s Joint Bioenergy Institute (JBEI), located in Emeryville, California. Other partners are the DOE’s Sandia National Laboratory, the University of California (UC) campuses of Berkeley and Davis, the Carnegie Institution for Science , and the DOE’s Lawrence Livermore National Laboratory (LLNL). JBEI’s primary scientific mission is to advance the development of the next generation of biofuels – liquid fuels derived from the solar energy stored in plant biomass. JBEI is one of three new U.S. Department of Energy (DOE) Bioenergy Research Centers (BRCs).

Berkeley Lab has a major role in two DOE Energy Innovation Hubs. The mission of the Joint Center for Artificial Photosynthesis (JCAP) is to find a cost-effective method to produce fuels using only sunlight, water, and carbon dioxide. The lead institution for JCAP is the California Institute of Technology and Berkeley Lab is the second institutional center. The mission of the Joint Center for Energy Storage Research (JCESR) is to create next-generation battery technologies that will transform transportation and the electricity grid. The DOE’s Argonne National Laboratory leads JCESR and Berkeley Lab is a major partner.