From The Arizona State University

4.19.24

Mary Beth Faller

marybeth.faller@asu.edu

ASU plugged into this next breakthrough in microchip tech with curriculum, partnerships with industry leaders

Illustration by Alex Davis and Alex Cabrera/ASU

Microchips are hot.

The tiny bits of silicon are integral to 21st-century life because they power the smartphones we rely on, the cars we drive and the advanced weaponry that is the backbone of national security. They’re so important that the disruption of the microchip supply chain during the pandemic became an urgent national security issue.

Also, microchips are literally hot.

Those tiny chips have mighty computing power, which builds up heat around the microchip. From the beginning, in the 1950s, manufacturers designed packaging — the materials around the chips — to mitigate heat, provide protection and enable electrical current to flow.

Over the decades, as the chips became more powerful, the packaging became more sophisticated.

Now, “advanced packaging” is a critical part of the design and manufacture of chips, not only to protect them from the heat generated by ever-increasing power but also as a way to actually improve their performance — critical as the strategy of adding more transistors on ever smaller chips, the practice that has driven the industry since the 1960s, reaches both its financial and physical limits.

The newest generation of advanced packaging is integrated with the chips during the manufacturing process to make them work faster and even combine different kinds of chips onto one wafer for super advanced capabilities like artificial intelligence.

It’s as if you had a glove that not only protected your hand but also made it stronger.

Arizona State University is poised to be a major player in this next breakthrough in microchip technology. The university is one of the few in the country that is teaching advanced packaging to its students, creating the skilled workforce that’s desperately needed by the semiconductor industry. A key asset in doing that is ASU’s partnerships with industry leaders to research the next innovations as well as create a cutting-edge production line.

ASU has launched a ground-breaking collaboration with Deca Technologies, a Tempe, Arizona-based provider of advanced packaging technology. ASU and Deca will create North America’s first fan-out wafer-level packaging research and development center. The new Center for Advanced Wafer-Level Packaging Applications and Development will expand domestic semiconductor manufacturing and drive advancements in artificial intelligence, machine learning, automotive electronics and high-performance computing.

In addition, ASU recently entered into a partnership with NXP Semiconductors focused on advanced packaging. Fueled by the support of the Arizona Commerce Authority, ASU received $17.5 million to expand research, development and workforce training.

It’s all part of a strategy launched several years ago by ASU to become a leader in the field of advanced packaging, according to Zachary Holman, a professor in the School of Electrical, Computer and Energy Engineering at ASU.

“ASU’s competitive advantage in advanced packaging stems from our scale, the innovativeness of our faculty and our partnerships, which extend both locally with companies like Deca Technologies, NXP and others, and farther afield,” he said.

“Advanced packaging will allow the semiconductor industry to keep growing, even though shrinking transistors is no longer the path forward. And here in Arizona we have an excellent advanced packaging industry, and it’s growing.”

Arizona and the future of semiconductor innovation: Arizona State University (ASU)

Video by ASU VisComm

The COVID-19 pandemic highlighted America’s dependency on Asia when supply chain disruptions led to critical shortages impacting consumer purchases of everything from computers to automobiles to home appliances.

In 2022, the bipartisan CHIPS and Science Act was signed into law, releasing $52 billion over five years to help the U.S. regain its superiority in semiconductor research, manufacturing and supply chain logistics.

ASU’s role in helping the U.S. become a leader in advanced packaging will enable a secure supply chain, said Holman, who also is vice dean for research and innovation in the Ira A. Fulton Schools of Engineering at ASU.

“A secure supply chain allows us to make the electronics that we need for everything from consumer products to vehicles to weapons for the defense industry,” he said.

Making chips do new tricks

Historically, electronics got better by making transistors smaller.

That’s a function of Moore’s Law, a 1965 prediction by Gordon Moore, co-founder of Intel, who said that the number of transistors on microchips would double every two years, increasing computing power while decreasing costs.

But Moore’s Law is no more, Holman said.

“We’ve reached a fundamental limit where we can’t make things better just by making transistors smaller anymore. And so we have to come up with a new way,” he said.

Advanced packaging was developed around 2000.

“Advanced packaging allows us to put chips together in new ways to achieve new functionalities, to speed up electronics, to make them do new tricks without making transistors smaller,” Holman said.

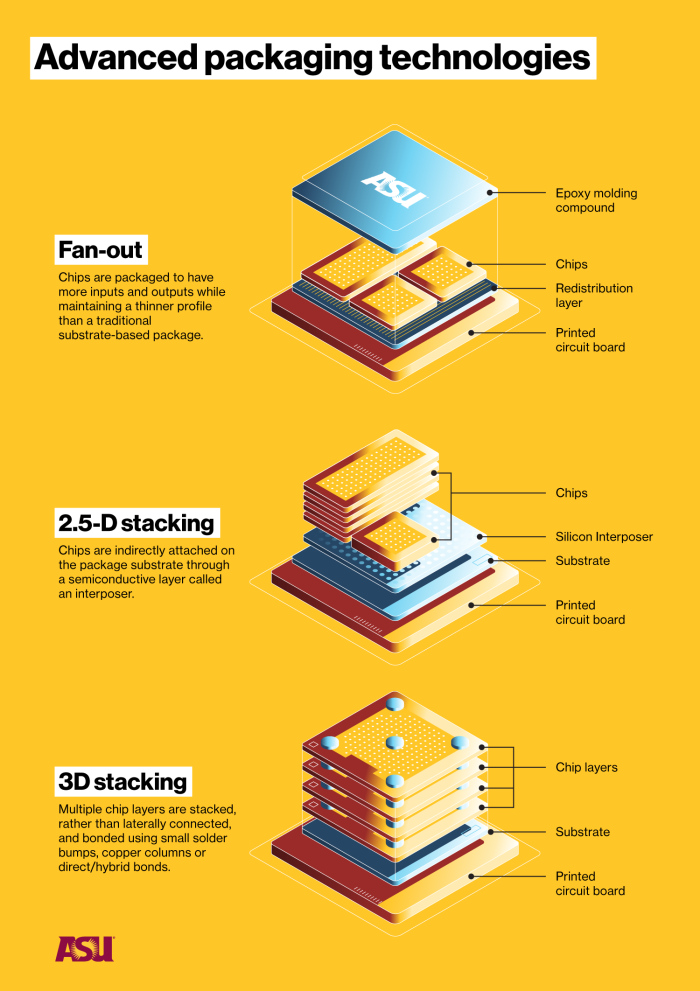

Different types of packaging are used for different applications. A smartphone combines different packaging for the graphics, the user interface and the power management. An autonomous vehicle that uses artificial intelligence is even more complex.

Tim Olson founded Deca Technologies in 2009, after leading research and development at semiconductor company Amkor.

“I had a passion to transform the way advanced packaging was done, and I felt we could do it a better way,” he said.

Deca Technologies specializes in a process called fan-out wafer-level packaging and provides components used in iPhones.

“Fan-out wafer-level packaging is very unique and, at a highest order, the fan-out part of it is ‘glue.’ So view fan-out as glue, and you glue together things that you want to put together, whether that’s a processor chip, a memory chip, a combination of memory chips, an RF (radio frequency) communication chip, a battery — whatever it is that you want to put together,” Olson said.

“There’s really no other packaging technology like it where you can glue those things together laterally, vertically, in any directions and orientations that you want.”

Even as advanced packaging technology has surged in the past several years, there’s still a long way to go, Olson said.

“Advanced packaging today, for all the buzz that we hear, is really in its infancy,” he said.

“Over the next decade, there will be orders of magnitude scaling required in advanced packaging to keep up with the demands of artificial intelligence, the real-time nature of autonomous vehicles and things like that.”

The new ASU-Deca Technologies collaboration — the Center for Advanced Wafer-Level Packaging Applications and Development — will be in the MacroTechnology Works facility in ASU’s Research Park in Tempe. MacroTechnology Works is a former Motorola semiconductor fabrication facility that ASU bought in 2004. It’s more than 250,000 square feet with more than 40,000 square feet of “clean room” space.

“This center will allow ASU and Deca to have a joint place, a set of tools, capabilities and people to further develop what is possible in packaging, as well as training the next generation workforce by having ASU students use the equipment in the center,” Holman said.

More than 20 new pieces of equipment will power the production line.

Olson said the new center will develop many types of solutions.

“It’s really the first fab in the U.S. where you have an open innovation platform where folks can come together, like students or industry users, producers, equipment companies, material companies, and work together on a foundation of technology that’s being provided by Deca and integrated by ASU,” he said.

Olson is excited for Deca Technologies work with students.

“The amazing advantage of students is their intellectual curiosity,” he said.

“When they’re working on a problem or working on a project and they see something that doesn’t quite work the way we’d like it to work, they ask enough questions and they dig into it enough to often create a better way to do it or to solve a fundamental problem that’s been hampering the technology for a long time.”

Building a semiconductor workforce

As part of its strategy to become a leader in advanced packaging, ASU started hiring experts to become faculty. One of them is Leslie Hwang, assistant professor in the School of Electrical, Computer and Energy Engineering, who creates software models that predict chip reliability.

“Packaging has become a more critical issue as technology is scaling,” she said.

“We’re trying to pack so much power and so much function into smaller domains that thermal issues are becoming critical. There’s not enough area (for heat) to dissipate.

“For a chip to function, you need a maximum temperature of 87 degrees or the chips are being fried, and you definitely don’t want that. A higher temperature means slower function and accelerated aging and mechanical stress — warping the material.”

Hwang uses machine learning to create computer models that analyze multiple, simultaneous factors — such as temperature and mechanical stress during manufacturing — to determine chip reliability.

“You need to predict the actual usage as much as possible in advance to do that,” she said.

“If you can predict well, you’re not only saving cost, but it can be a foundation to build a better design. And by coming up with more effective packaging techniques, we can actually elongate the lifetime of the electronic from the consumer side.”

ASU is one of the few universities in the country that’s teaching advanced packaging in its engineering curriculum, with a focus on the interdisciplinary nature of the industry.

“Here at ASU, we currently have 200 students-plus doing packaging-related courses,” said Chris Bailey, professor in the School of Electrical, Computer and Energy Engineering.

“We’re seeing significant growth in those student numbers, but also we are engaging with the wider community and looking at different activities to ensure we have the workforce for the future.”

Bailey teaches a graduate course on the fundamentals of packaging, from the 1960s to today.

“And this is one of the great things about ASU — I have students there from chemical engineering, from materials science, from electrical engineering and from mechanical engineering because they’re all important for advanced semiconductor packaging,” he said.

He also teaches a course on design and modeling for advanced packaging.

“So they’re sitting in front of computers doing electronic (computer-assisted design), they’re undertaking thermal calculations, electromagnetic calculations, the mechanical calculations. But they also learn the need to understand metrology and materials behavior.

“And that’s where we need that multidisciplinary knowledge for the students, and also for the next generation of advanced semiconductor packaging engineers.”

Bailey said that industry partnerships teach students the real-world challenges of manufacturing.

“We’re engaging with companies to ask, ‘What if we do it this way?’” he said.

While designing and manufacturing microelectronics to be more powerful and efficient is a key to America’s advancement, ASU is also helping to solve the critical problem of producing the workforce to do it.

“With all the buzz you hear about chips and semiconductors, with TSMC coming to town, with Intel and with the $8 billion announced recently from the U.S. government and all the things happening in the Valley … it’s still incredibly difficult for us to find the right talent,” Olson said.

“So I think what this partnership brings is the ability to create a very significantly enhanced pool of talent for not only for our business, but for all the businesses related to the semiconductor industry.”

Sally Morton, executive vice president of ASU’s Knowledge Enterprise, sees the role of the university as a strength both locally and nationally.

“Arizona State University is advancing the local semiconductor industry and positioning our state as a leader in semiconductor research, manufacturing and job growth,” Morton said. “With help from our industry partners, we are bridging the gap between lab to fab with advanced and innovative packaging solutions to scale up production methods and optimize efficiency and cost-effectiveness.

“This will strengthen domestic production and the nation’s critical supply chain, while enhancing the U.S.’s competitiveness in the global semiconductor market in areas such as electronics, telecommunications and defense.”

Different types of packaging are used for different applications. Illustration by Alex Davis and Alex Cabrera/ASU

See the full article here.

Comments are invited and will be appreciated, especially if the reader finds any errors which I can correct.

five-ways-keep-your-child-safe-school-shootings

Please help promote STEM in your local schools.

The Arizona State University Tempe Campus.

The Arizona State University is a public research university in the Phoenix metropolitan area. Founded in 1885 by the 13th Arizona Territorial Legislature, ASU is one of the largest public universities by enrollment in the U.S.

One of three universities governed by the Arizona Board of Regents, The Arizona State University is a member of the Association of American Universities and classified among “R1: Doctoral Universities – Very High Research Activity.” The Arizona State University has more than 150,000 students attending classes, with more than 38,000 students attending online, and over 90,000 undergraduates and more nearly 20,000 postgraduates across its five campuses and four regional learning centers throughout Arizona. The Arizona State University offers 350 degree options from its 17 colleges and more than 170 cross-discipline centers and institutes for undergraduates students, as well as more than 400 graduate degree and certificate programs. The Arizona State Sun Devils compete in 26 varsity-level sports in the NCAA Division I Pac-12 Conference and is home to over 1,100 registered student organizations.

The Arizona State University ‘s charter, approved by the board of regents in 2014, is based on the New American University model created by The Arizona State University President Michael M. Crow upon his appointment as the institution’s 16th president in 2002. It defines The Arizona State University as “a comprehensive public research university, measured not by whom it excludes, but rather by whom it includes and how they succeed; advancing research and discovery of public value; and assuming fundamental responsibility for the economic, social, cultural and overall health of the communities it serves.” The model is widely credited with boosting The Arizona State University ‘s acceptance rate and increasing class size.

The university’s faculty of more than 4,700 scholars has included Nobel laureates, Pulitzer Prize winners, MacArthur Fellows, and National Academy of Sciences members. Additionally, among the faculty are Fulbright Program American Scholars, National Endowment for the Humanities fellows, American Council of Learned Societies fellows, members of the Guggenheim Fellowship, members of the American Academy of Arts and Sciences, members of National Academy of Inventors, National Academy of Engineering members and National Academy of Medicine members. The National Academies has bestowed “highly prestigious” recognition on a large number of Arizona State University faculty members.

History

The Arizona State University was established as the Territorial Normal School at Tempe on March 12, 1885, when the 13th Arizona Territorial Legislature passed an act to create a normal school to train teachers for the Arizona Territory. The campus consisted of a single, four-room schoolhouse on a 20-acre plot largely donated by Tempe residents George and Martha Wilson. Classes began with 33 students on February 8, 1886. The curriculum evolved over the years and the name was changed several times; the institution was also known as Tempe Normal School of Arizona (1889–1903), Tempe Normal School (1903–1925), Tempe State Teachers College (1925–1929), Arizona State Teachers College (1929–1945), Arizona State College (1945–1958) and, by a 2–1 margin of the state’s voters, The Arizona State University in 1958.

In 1923, the school stopped offering high school courses and added a high school diploma to the admissions requirements. In 1925, the school became the Tempe State Teachers College and offered four-year Bachelor of Education degrees as well as two-year teaching certificates. In 1929, the 9th Arizona State Legislature authorized Bachelor of Arts in Education degrees as well, and the school was renamed The Arizona State Teachers College. Under the 30-year tenure of president Arthur John Matthews (1900–1930), the school was given all-college student status. The first dormitories built in the state were constructed under his supervision in 1902. Of the 18 buildings constructed while Matthews was president, six are still in use. Matthews envisioned an “evergreen campus,” with many shrubs brought to the campus, and implemented the planting of 110 Mexican Fan Palms on what is now known as Palm Walk, a century-old landmark of the Tempe campus.

During the Great Depression, Ralph Waldo Swetman was hired to succeed President Matthews, coming to The Arizona State Teachers College in 1930 from The Humboldt State Teachers College where he had served as president. He served a three-year term, during which he focused on improving teacher-training programs. During his tenure, enrollment at the college doubled, topping the 1,000 mark for the first time. Matthews also conceived of a self-supported summer session at the school at The Arizona State Teachers College, a first for the school.

1930–1989

In 1933, Grady Gammage, then president of The Arizona State Teachers College at Flagstaff, became president of The Arizona State Teachers College at Tempe, beginning a tenure that would last for nearly 28 years, second only to Swetman’s 30 years at the college’s helm. Like President Arthur John Matthews before him, Gammage oversaw the construction of several buildings on the Tempe campus. He also guided the development of the university’s graduate programs; the first Master of Arts in Education was awarded in 1938, the first Doctor of Education degree in 1954 and 10 non-teaching master’s degrees were approved by the Arizona Board of Regents in 1956. During his presidency, the school’s name was changed to Arizona State College in 1945, and finally to The Arizona State University in 1958. At the time, two other names were considered: Tempe University and State University at Tempe. Among Gammage’s greatest achievements in Tempe was the Frank Lloyd Wright-designed construction of what is Grady Gammage Memorial Auditorium/ASU Gammage. One of the university’s hallmark buildings, Arizona State University Gammage was completed in 1964, five years after the president’s (and Wright’s) death.

Gammage was succeeded by Harold D. Richardson, who had served the school earlier in a variety of roles beginning in 1939, including director of graduate studies, college registrar, dean of instruction, dean of the College of Education and academic vice president. Although filling the role of acting president of the university for just nine months (Dec. 1959 to Sept. 1960), Richardson laid the groundwork for the future recruitment and appointment of well-credentialed research science faculty.

By the 1960s, under G. Homer Durham, the university’s 11th president, The Arizona State University began to expand its curriculum by establishing several new colleges and, in 1961, the Arizona Board of Regents authorized doctoral degree programs in six fields, including Doctor of Philosophy. By the end of his nine-year tenure, The Arizona State University had more than doubled enrollment, reporting 23,000 in 1969.

The next three presidents—Harry K. Newburn (1969–71), John W. Schwada (1971–81) and J. Russell Nelson (1981–89), including and Interim President Richard Peck (1989), led the university to increased academic stature, the establishment of The Arizona State University West campus in 1984 and its subsequent construction in 1986, a focus on computer-assisted learning and research, and rising enrollment.

1990–present

Under the leadership of Lattie F. Coor, president from 1990 to 2002, The Arizona State University grew through the creation of the Polytechnic campus and extended education sites. Increased commitment to diversity, quality in undergraduate education, research, and economic development occurred over his 12-year tenure. Part of Coor’s legacy to the university was a successful fundraising campaign: through private donations, more than $500 million was invested in areas that would significantly impact the future of The Arizona State University. Among the campaign’s achievements were the naming and endowing of Barrett, The Honors College, and the Herberger Institute for Design and the Arts; the creation of many new endowed faculty positions; and hundreds of new scholarships and fellowships.

In 2002, Michael M. Crow became the university’s 16th president. At his inauguration, he outlined his vision for transforming The Arizona State University into a “New American University”—one that would be open and inclusive, and set a goal for the university to meet Association of American Universities criteria and to become a member. Crow initiated the idea of transforming The Arizona State University into “One university in many places”—a single institution comprising several campuses, sharing students, faculty, staff and accreditation. Subsequent reorganizations combined academic departments, consolidated colleges and schools, and reduced staff and administration as the university expanded its West and Polytechnic campuses. The Arizona State University’s Downtown Phoenix campus was also expanded, with several colleges and schools relocating there. The university established learning centers throughout the state, including The Arizona State University Colleges at Lake Havasu City and programs in Thatcher, Yuma, and Tucson. Students at these centers can choose from several Arizona State University degree and certificate programs.

During Crow’s tenure, and aided by hundreds of millions of dollars in donations, The Arizona State University began a years-long research facility capital building effort that led to the establishment of the Biodesign Institute at The Arizona State University, the Julie Ann Wrigley Global Institute of Sustainability, and several large interdisciplinary research buildings. Along with the research facilities, the university faculty was expanded, including the addition of Nobel Laureates. Since 2002, the university’s research expenditures have tripled and more than 1.5 million square feet of space has been added to the university’s research facilities.

The economic downturn that began in 2008 took a particularly hard toll on Arizona, resulting in large cuts to The Arizona State University ‘s budget. In response to these cuts, The Arizona State University capped enrollment, closed some four dozen academic programs, combined academic departments, consolidated colleges and schools, and reduced university faculty, staff and administrators; however, with an economic recovery underway in 2011, the university continued its campaign to expand the West and Polytechnic Campuses, and establish a low-cost, teaching-focused extension campus in Lake Havasu City.

The Arizona State University’s research funding has almost tripled. Degree production has increased by 45 percent. And thanks to an ambitious aid program, enrollment of students from Arizona families below poverty is up 647 percent.”

In 2015, the Thunderbird School of Global Management became the fifth Arizona State University campus, as the Thunderbird School of Global Management at The Arizona State University. Partnerships for education and research with Mayo Clinic established collaborative degree programs in health care and law, and shared administrator positions, laboratories and classes at the Mayo Clinic Arizona campus.

The Beus Center for Law and Society, the new home of The Arizona State University’s Sandra Day O’Connor College of Law, opened in fall 2016 on the Downtown Phoenix campus, relocating faculty and students from the Tempe campus to the state capital.